Description

| PACKAGING

1/4″ x 3″ x 100′ |

(Standard Size Rolls)

20 rolls/bale |

| 1/4″ x 4″ x 100′ 6.4 mm x 101.6 mm x 30.5 m |

15 rolls/bale |

| 1/4″ x 6″ x 100′ 6.4 mm x 152.4 mm x 30.5 m |

10 rolls/bale |

| 1/4″ x 8″ x 100′ 6.4 mm x 203.2 mm x 30.5 m |

7 rolls/bale |

| 1/4″ x 48″ x 100′ 6.4 mm x 1.22 m x 30.5 m |

1 roll/bale |

| 1/2″ x 3″ x 50′ 12.7 mm x 76.2 mm x 15.2 m |

20 rolls/bale |

| 1/2″ x 3 1/2″ x 50′ 12.7 mm x 88.9 mm x 15.2m |

17 rolls/bale |

| 1/2″ x 4″ x 50′ 12.7 mm x 101.6 mm x 15.2 m |

15 rolls/bale |

| 1/2″ x 5″ x 50′ 12.7 mm x 127 mm x 15.2 m |

12 rolls/bale |

| 1/2″ x 6″ x 50′ 12.7 mm x 152.4 mm x 15.2 m |

10 rolls/bale |

| 1/2″ x 8″ x 50′ 12.7 mm x 203.2 mm x 15.2 m |

7 rolls/bale |

| 1/2″ x 48″ x 50′ 12.7 mm x 1.22 m x 15.2 m |

1 roll/bale |

*Special sizes available upon request.

SPECIFICATIONS

- ASTM D 4819, Type II

TECHNICAL DATA

| TEST METHOD | TYPICAL VALUE | |

| Density | ASTM D 1622 | 2.0 lb./ft.3 (32.04 kg/m3) |

| Compression | ||

| 10% Deflection | ASTM D 3575 | 10 psi (69 KPa) max. |

| 80% Deflection | ASTM D 3575 | 125 psi (862.49 KPa) max. |

| Tensile Strength | ASTM D 3575 | 55 psi (379.50 KPa) |

| Water Absorption | ASTM D 3575 | 0.5% vol. max. |

| Temperature Stability | N/A | -40º F to 160º F (-40º C to 71º C) |

These physical properties are typical, but should not be used in specifying material due to differences that could result from variations in testing methods.

APPLICATION

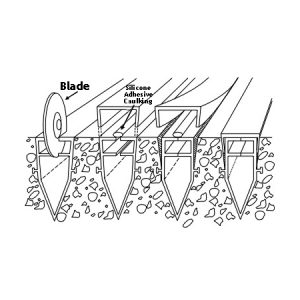

Attach DECK-O-FOAM securely to the existing concrete slab, coping, or form with tape or mechanical fasteners prior to pouring the next slab. Make sure that DECK-O-FOAM is level with the desired slab surfaces before finishing. If specifications require the use of a cold-applied sealant, remove the pre-scored strip and apply the sealant following the manufacturer’s instructions.

LEED INFORMATION

May help contribute to LEED credits:

- MR Credit 2: Construction Waste Management

- MR Credit 5: Regional Materials

This material last updated May 2014.