Description

TECHNICAL DATA

| Test | Results |

| Color: | White |

| Thickness: | 40 mils (1 mm) |

| Pliability @ -25° F (-32° C) | No effect |

| Tensile Strength Film ASTM D 412 modified (MD): ASTM D 882 (MD): lb/in. |

4000 psi (27.6 MPa) 23.5 lb/in. (4.1 N/mm) |

| Elongation Film: ASTM D 412 modified (MD, %): ASTM D 882, (MD, %): |

400 (Typical) 400 Min. |

| Puncture Resistance: ASTM E 154 |

40 lbf (178 N) Min. |

| Water Vapor Permeance (free film) ASTM E-96, Procedure B |

0.035 Perms |

| Water Absorption (% by weight): ASTM D 1970 ASTM D 570-81 |

0.25 Max 0.1 Max. |

| Application Temperature: | 40° F (4° C) Min. |

| Low Temperature Flexibility @ -22° F (-30° C) (CGSB 37-gp-56m) |

PASS |

| Service Temperature | -40° F to 158° F |

| Lap Peel Strength @ 39° F (4° C) (ASTM D 903, 180 Bend) |

10 lbf/in width (1.75 N/mm) |

**Air leakage tested per ASTM E 283

FEATURES/BENEFITS

- Low permeability – prevents the transmission of air and inhibits moisture vapor through porous building materials.

- Provides a complete above-grade air, vapor, and water barrier on a variety of construction materials.

- Controlled thickness membrane is ideal for air barrier applications.

- Cross-laminated polyethylene film has excellent tensile strength, elongation, and tear resistance.

- Modified membrane is flexible at low temperatures.

- Excellent adhesion to prepared substrates of precast concrete, cast-in-place concrete, masonry (concrete block), interior and exterior gypsum board, Styrofoam, primed steel, aluminum mill finish, anodized aluminum, primed galvanized metal, drywall, and plywood.

- Self-healing characteristics facilitate recovery if minimal damage is sustained under normal use applications.

- No flame required.

- Low temperature version also available – can be applied at temperatures between 20˚ F (-7˚ C) and 60° F (16° C).

- AIR-SHIELD XLT can be applied at minimum temperatures of 0° F (-18° C).

Air leakage tested per ASTM E 283, ASTM E 2178-01, and ASTM E 2357

|

Pressure |

Air Leakage |

Results for |

Air Leakage |

Results for |

|

|

Pa |

lb./ft.² |

L/S/m² |

cfm/ft.² |

||

|

75 |

1.57 |

0.02 |

Less than 0.02 |

0.004 |

Less than 0.004 |

APPLICATION

Surface Preparation … All surfaces to be protected must be clean, dry, frost-free, and smooth. Remove any sharp protrusions and repair all defects. All surfaces to receive AIR-SHIELD must be clean of oil, dust, and excess mortar. Strike masonry joints flush. Concrete surfaces must be smooth and without large voids, spalled areas, or sharp protrusions. Concrete must be cured a minimum of 14 days and must be dry before AIR-SHIELD is applied. Where curing compounds are used, they must be clear resin-based, without oil, wax or pigments. Prepare substrate per manufacturer’s instruction prior to application of membrane.

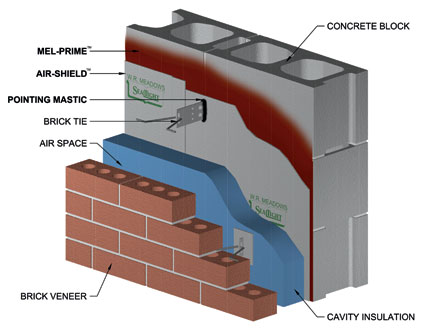

All surfaces to which AIR-SHIELD is to be applied must be addressed with MEL-PRIME™ or MEL-PRIME W/B adhesive from W. R. MEADOWS. MEL-PRIME may be applied to an area that is to be covered the same day. Uncovered areas must be re-addressed the next day. See container for complete application directions, drying information, and precautions.

Application Method… AIR-SHIELD self-adhesive air/vapor and liquid moisture barrier can be applied at minimum temperatures of 40º F (4º C). Apply membrane to surface addressed with MEL-PRIME by removing release paper and rolling membrane firmly into place. Remove release paper only as membrane is being applied. Ensure membrane is fully adhered and remove all wrinkles and/or fish mouths. Cut AIR-SHIELD membrane with a utility knife to detail around protrusions and masonry reinforcing. Seal all end laps and protrusions with POINTING MASTIC from W. R. MEADOWS. Overlap subsequent courses of membrane a minimum of 2″ (5.1 cm). Vertical terminations of AIR-SHIELD should either be tied into the wall system or mechanically fastened with TERMINATION BAR from W. R. MEADOWS. AIR-SHIELD is not designed for permanent exposure. Good construction practices call for application of insulation as soon as possible to protect the air barrier.

When used as a flexible wall flashing, AIR-SHIELD should be recessed ½” (13 mm) from the face of the masonry. Flashing should not be permanently exposed to sunlight. Do not allow the rubberized asphalt surface of the flashing membrane to come in contact with sealants containing solvents, creosote, uncured coal tar products, EPDM, or PVC components.

Cleanup … Tools, etc. can be cleaned with mineral spirits, paint thinner or aromatic solvent.

COVERAGE

Coverage is approximately 240 ft.² (22.3 m²). Net coverage when lapped 2″ (5.1 cm) is 228 ft.² (21.1 m²).

SAFETY & TOXICITY

No adverse effects expected with normal product use. Cotton work gloves and safety glasses are recommended. Refer to Material Safety Data Sheet for complete health and safety information.

BELOW-GRADE PROTECTION

W. R. MEADOWS offers the following moisture and vaporproofing products, providing the specifying authority a single-source system for the entire building envelope:

PREMOULDED MEMBRANE® VAPOR SEAL WITH PLASMATIC CORE® (PMPC) for horizontal vapor proofing applications. Refer to data sheet #711.

MEL-ROL® waterproofing membrane. Refer to data sheet #717.

MEL-ROL PRECON blindslide/waterproofing membrane. Refer to data sheet #714-F.

MEL-DRAIN™ rolled matrix drainage system is designed to protect vaporproofing and waterproofing membranes in either horizontal or vertical applications. Refer to data sheet #719.

MEL-ROL LM single-component, water-based, polymer-modified, cold-applied waterproofing membrane. Refer to data sheet #714-A.

PERMINATOR underslab vapor barrier. Refer to data sheet #723.

ACCESSORIES

MEL-PRIME W/B… This water-based adhesive prepares surfaces for AIR-SHIELD membrane application. Product is ready to use and requires no additional mixing. MEL-PRIME W/B emits no unpleasant odors and works with all waterproofing membranes from W. R. MEADOWS. Can be applied easily by manual spraying or with a roller. Product is VOC-compliant. MEL-PRIME W/B is ideal for use at temperatures of 40° F (4° C) and above.

Coverage: 250 – 350 ft.²/gal. (6.14 to 8.6 m²/L)

Packaging: 1 Gallon (3.79 L) Units, 4/Carton and 5 Gallon (18.93 L) Pails

MEL-PRIME Adhesive… This solvent-based adhesive can be used at temperatures below 40° F (4° C) and above. Can be applied with a roller or brush.

Coverage: 250 – 300 ft.²/gal. (6.14 to 7.4 m²/L)

Packaging: 1 Gallon (3.79 L) Cans and 5 Gallon (18.93 L) Pails

TERMINATION BAR …As an option, TERMINATION BAR may be used to mechanically fasten the membrane.

Packaging: (25) 10′ pieces per 20 lb. carton (250 lineal ft.)

POINTING MASTIC… Used for sealing exterior vertical and horizontal terminations, laps, around protrusions, and top edges of TERMINATION BAR.

Coverage: Approximately 200 lineal ft. (61 m) per gallon (3.79 L) when used as directed.

Packaging: 5 Gallon (18.93 Liter) Pails or 29 oz.

(857.65 ml) cartridges, 12/Carton

LEED INFORMATION

May help contribute to LEED credits:

- EA Credit 1: Optimize Energy Performance

- IEQ Credit 3.1: Construction IAQ Management Plan: During Construction

- IEQ Credit 7.1: Thermal Comfort – Design

- MR Credit 2: Construction Waste Management

- MR Credit 5: Regional Materials

This material last updated March 2012.