AIR-SHIELD LMP – Vapor Permeable Air Barrier

AIR-SHIELDTM LMP

Liquid Membrane Vapor Permeable Air Barrier

DESCRIPTION

AIR-SHIELD LMP is a water-based air/liquid moisture barrier that cures to form a tough, seamless, elastomeric membrane. AIR-SHIELD LMP exhibits excellent resistance to air leakage. When properly applied as a drainage plane, AIR-SHIELD LMP prohibits liquid water intrusion into the substrate.

USES

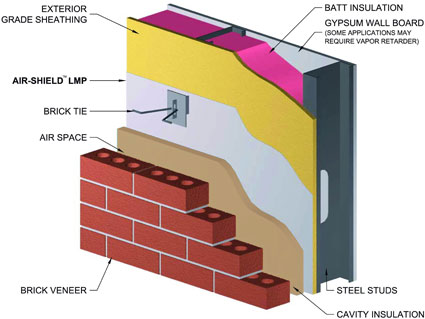

AIR-SHIELD LMP has been specifically formulated to act as an air and liquid moisture barrier, allowing vapor to pass through it. It may be applied to most common surfaces and integrated into various wall systems. AIR-SHIELD LMP is suitable for both new construction and retrofit applications.

FEATURES/BENEFITS

- High permeability – allows the transmission of moisture vapor through porous building materials.

- Highly flexible – bridges cracks, which may form in the substrate.

- UV resistant – gray membrane can be left exposed up to six months. Black membrane can be exposed for an indefinite period and is ideal for exposed applications, such as beneath rain screen panels.

- User friendly – single-component, water-based technology allows for simple, safe application and easy cleanup.

- Liquid applied – simplifies detailing and assures a monolithic, seamless membrane when applied to a rough or smooth surface.

- Sprayable – with appropriately configured airless spray equipment – low application costs.

- Excellent adhesion – remains firmly bonded to the substrate, even when applied over damp surfaces.

- Self-sealing – Nails and fasteners can be used without compromising performance.

- Low VOC content.

PACKAGING

5 Gallon (18.93 Liter) Pails

55 Gallon (208.20 Liter) Drums

COVERAGE

Application Rate: 25 ft.2/gal. (0.6 m2/L)

Wet Film Thickness: 60 mil (1.5 mm)

Cured Film Thickness: 30 mil (0.8 mm)

SHELF LIFE

When stored indoors in original, unopened containers at temperatures between 40° – 90° F (4° – 32° C), shelf life is one year from date of manufacture.

SPECIFICATIONS

- Exceeds Air Barrier Association of America (ABAA) requirements for fluid-applied air barriers.

- Exceeds ABAA maximum assembly air leakage requirements when tested in accordance with ASTM E 2357.

- Exceeds ABAA maximum material air leakage requirements when tested in accordance with ASTM E 2178.

- Exceeds the requirements of the Massachusetts Commercial Energy Code for Building Envelope Systems.

- 2010 National Building Code of Canada

- Complies with all current federal, state, and local maximum allowable VOC requirements, including U.S. EPA, LADCO, SCAQMD, and OTC.

- Complies with Canada VOC Concentration Limits for Architectural Coatings Regulations.